Gm Cylinder Deactivation Problems: Quick Fixes Unveiled

GM Cylinder Deactivation problems often stem from faulty lifters or engine control issues. These can lead to rough idling, reduced performance, and warning lights.

Cylinder deactivation technology enhances fuel efficiency by shutting down half of the engine’s cylinders under light loads. While this feature can save money at the pump, it sometimes leads to performance issues. Drivers may experience problems like engine noise, decreased acceleration, or vibrations.

These symptoms can be frustrating and may affect overall vehicle reliability. Regular maintenance and timely diagnostics can help identify and resolve these issues early. Understanding the underlying causes of GM cylinder deactivation problems ensures a smoother driving experience and prolongs the life of your vehicle. Prioritize addressing any symptoms promptly to maintain optimal performance.

Introduction To Gm Cylinder Deactivation

GM Cylinder Deactivation technology allows engines to save fuel. It works by shutting down some cylinders during light load conditions. This feature enhances fuel efficiency without sacrificing performance. However, it can lead to various problems that owners should know.

Purpose And Benefits

The primary purpose of GM Cylinder Deactivation is to improve fuel economy. This system offers several benefits:

- Increased Fuel Efficiency: Reduces fuel consumption during light driving.

- Lower Emissions: Emits fewer harmful gases into the environment.

- Enhanced Performance: Maintains power when needed.

- Cost Savings: Saves money on gas over time.

Many drivers appreciate these advantages. However, the technology is not without its issues.

Common Issues Encountered

GM Cylinder Deactivation can cause several problems, including:

- Rough Idling: Some drivers report uneven engine vibrations.

- Loss of Power: Engine may struggle during acceleration.

- Oil Consumption: Increased oil usage can occur.

- Check Engine Light: May illuminate due to system faults.

These issues can affect driving experience. Regular maintenance helps prevent many of these problems.

| Problem | Description | Potential Solution |

|---|---|---|

| Rough Idling | Engine vibrations during idle. | Check spark plugs and injectors. |

| Loss of Power | Engine struggles under acceleration. | Inspect throttle body and sensors. |

| Oil Consumption | Increased oil usage over time. | Monitor oil levels and change regularly. |

| Check Engine Light | Indicates system faults. | Use a diagnostic tool to identify issues. |

Understanding these problems helps drivers take action. Knowledge of GM Cylinder Deactivation aids in maintaining vehicle performance.

Identifying Cylinder Deactivation Problems

Cylinder deactivation can improve fuel efficiency. However, issues can arise. Recognizing these problems early helps avoid costly repairs. Understanding the symptoms and using proper diagnostic tools are essential.

Symptoms To Watch For

Watch for these common symptoms:

- Engine Misfire: A rough idle or uneven running.

- Decreased Power: Noticeable loss of acceleration.

- Poor Fuel Economy: Increased fuel consumption.

- Check Engine Light: Dashboard warning appears.

- Unusual Noises: Knocking or tapping sounds from the engine.

Pay attention to these signs. Early detection can save you money and time.

Diagnostic Tools And Methods

Use these tools to diagnose cylinder deactivation issues:

| Tool/Method | Description |

|---|---|

| OBD-II Scanner | Reads engine codes. Helps identify issues. |

| Compression Test | Checks cylinder pressure. Detects leaks or faults. |

| Visual Inspection | Check for oil leaks or damaged components. |

| Fuel Trim Analysis | Monitors air-fuel mixture. Identifies fueling problems. |

These methods help pinpoint the problem. Regular maintenance can prevent issues.

Quick Fixes For Common Issues

GM Cylinder Deactivation can sometimes cause problems. Quick fixes can help resolve these issues. Let’s explore some simple solutions to get your vehicle running smoothly again.

Resetting The System

Sometimes, the system needs a reset. This can fix many minor problems. Follow these steps:

- Turn off the engine.

- Disconnect the battery. Wait for 10 minutes.

- Reconnect the battery.

- Start the engine and let it idle for 10 minutes.

- Drive the vehicle for a short distance.

This process can help reset the system’s settings. It often improves performance and efficiency.

Simple Maintenance Tips

Regular maintenance can prevent many issues. Here are some tips:

- Check engine oil: Keep oil levels full and clean.

- Inspect spark plugs: Replace them if they show wear.

- Clean the air filter: A clean filter helps the engine breathe better.

- Monitor coolant levels: Ensure the engine doesn’t overheat.

- Use quality fuel: This can enhance performance and efficiency.

These simple steps can help maintain your vehicle. Regular checks reduce the risk of major problems.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Spark Plug Replacement | Every 30,000 miles |

| Air Filter Check | Every 15,000 miles |

| Coolant Level Check | Monthly |

Following these tips ensures your vehicle stays in top shape. Regular maintenance leads to fewer problems.

Addressing Specific Fault Codes

Understanding fault codes is vital for tackling Gm Cylinder Deactivation problems. Each code points to specific issues. Here, we focus on troubleshooting P3400, P3425, and P3401 to P3408.

Troubleshooting P3400 And P3425

P3400 indicates a problem with the cylinder deactivation system. This code often shows when the engine control module (ECM) detects a malfunction. Here’s how to troubleshoot:

- Check the wiring and connectors for damage.

- Inspect the VVT (Variable Valve Timing) solenoid.

- Test the oil pressure. Low oil pressure can trigger this code.

- Scan for other fault codes. Sometimes, multiple issues exist.

P3425 points to problems with the cylinder deactivation performance. Follow these steps:

- Ensure the engine oil level is adequate.

- Verify the operation of the camshaft actuator.

- Check for vacuum leaks around the intake manifold.

- Inspect the exhaust system for restrictions.

Dealing With P3401 To P3408

The codes P3401 to P3408 relate to cylinder deactivation faults. Each code specifies a different issue. Here’s a breakdown:

| Fault Code | Description | Common Causes |

|---|---|---|

| P3401 | Fault in the left bank cylinder deactivation | Faulty solenoid, wiring issues |

| P3402 | Fault in the right bank cylinder deactivation | Faulty solenoid, oil pressure issues |

| P3403 | Faulty signal from camshaft position sensor | Bad sensor, wiring problems |

| P3404 | Camshaft actuator performance issue | Low oil pressure, defective actuator |

| P3405 | Improper cylinder deactivation timing | Timing chain issues, ECM failure |

| P3406 | Fault in the cylinder deactivation system | Wiring damage, solenoid failure |

| P3407 | Excessive oil pressure | Clogged oil filter, pump failure |

| P3408 | Misfire during cylinder deactivation | Bad spark plugs, fuel injector issues |

Identifying the right code helps in effective troubleshooting. Proper diagnosis prevents further engine damage. Keep the engine well-maintained to avoid these issues.

Advanced Repair Techniques

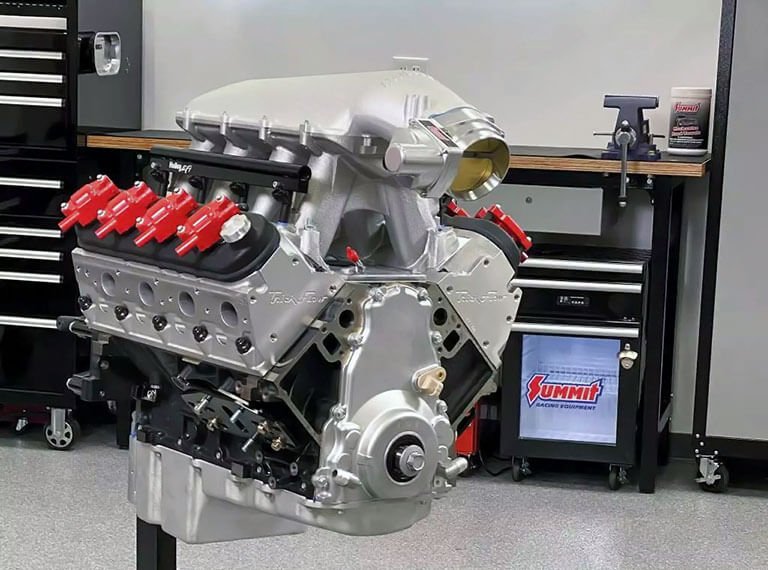

GM Cylinder Deactivation can lead to various issues. Advanced repair techniques help address these problems effectively. Two common solutions are solenoid replacement and lifter replacement. Each method requires careful steps for success.

Solenoid Replacement

The solenoid controls the cylinder deactivation system. A malfunctioning solenoid can cause poor engine performance. Follow these steps for a successful replacement:

- Disconnect the battery.

- Locate the solenoid on the engine.

- Remove any connectors or bolts securing it.

- Replace the old solenoid with a new one.

- Reconnect all connectors and bolts.

- Reconnect the battery.

After replacement, check for any error codes. A diagnostic tool can help with this.

Lifter Replacement Procedure

Lifter replacement is crucial for restoring engine efficiency. A faulty lifter can lead to ticking noises and loss of power. Here’s how to replace it:

- Gather necessary tools: socket set, torque wrench, and new lifters.

- Remove the valve cover to access the lifters.

- Take out the old lifters carefully.

- Install the new lifters in their designated positions.

- Reassemble the valve cover and secure it tightly.

- Start the engine and listen for any unusual sounds.

Replacing the lifters can improve engine performance significantly. Regular checks can prevent major issues.

Preventive Measures And Maintenance

Preventive measures and maintenance are crucial for GM cylinder deactivation systems. Regular upkeep can prevent costly repairs. Knowing what to check can save time and money.

Regular Check-ups

Regular check-ups help identify issues early. Schedule maintenance every 3,000 to 5,000 miles. Include these checks:

- Engine oil level and quality

- Coolant levels

- Air filter condition

- Spark plugs

- Fuel injectors

Use a professional mechanic for a thorough inspection. Look for signs of wear or damage. Address small problems before they become big ones.

Best Practices For Engine Health

Follow these best practices for optimal engine health:

- Use Quality Oil: Always use manufacturer-recommended oil.

- Regular Oil Changes: Change oil every 5,000 miles or as needed.

- Monitor Engine Temperature: Ensure the engine does not overheat.

- Drive Smoothly: Avoid rapid acceleration and hard braking.

- Keep the Engine Clean: Remove dirt and debris regularly.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Oil Change | Every 5,000 miles | Prevents engine wear |

| Coolant Check | Every 6 months | Prevents overheating |

| Filter Replacement | Every 15,000 miles | Ensures clean air and fuel |

Professional Help Vs. Diy

Dealing with GM cylinder deactivation problems can be tricky. Many car owners wonder whether to fix issues themselves or seek professional help. Understanding the risks and benefits of each option is crucial.

When To Seek Professional Help

Some situations require expert advice. Here are signs to consider:

- Warning lights appear on your dashboard.

- Engine sounds unusual or knocking.

- Fuel efficiency has suddenly dropped.

- Excessive smoke from the exhaust.

Professional mechanics have the tools and experience. They can quickly identify the problem. Ignoring these signs may lead to more costly repairs later.

Resources For Diy Enthusiasts

Some car owners prefer DIY repairs. Here are helpful resources:

- Online forums: Join communities for advice and support.

- Video tutorials: Watch step-by-step guides on platforms like YouTube.

- Repair manuals: Purchase or borrow manuals specific to your vehicle.

Keep these tips in mind:

- Assess your skill level before starting repairs.

- Gather all necessary tools and parts.

- Follow safety guidelines at all times.

DIY can be rewarding. Yet, understanding your limits is important. Don’t hesitate to call a professional if needed.

Final Thoughts On Cylinder Deactivation

Cylinder deactivation is a technology used to improve fuel efficiency. It helps vehicles use fewer resources while maintaining performance. However, it also comes with some challenges. Understanding these issues can help car owners make informed decisions.

Balancing Performance And Efficiency

The main goal of cylinder deactivation is to enhance fuel economy. It allows the engine to deactivate certain cylinders during light loads. This reduces fuel consumption without sacrificing power.

Key benefits include:

- Increased Fuel Efficiency: Drivers can save money at the pump.

- Reduced Emissions: Fewer pollutants mean a cleaner environment.

- Enhanced Performance: Engines can switch back to full power when needed.

Challenges include:

- Engine Wear: Deactivating cylinders can lead to uneven wear.

- Complexity: More components can mean more potential for failure.

- Driver Experience: Some may notice changes in engine sound or feel.

The Future Of Cylinder Deactivation

The future looks promising for cylinder deactivation technology. Automakers are investing in advanced systems. These systems aim to minimize drawbacks while maximizing benefits.

Future trends may include:

- Improved Software: Better algorithms can enhance cylinder activation.

- Hybrid Integration: Combining cylinder deactivation with hybrid technology.

- Consumer Awareness: Educating drivers on the benefits and issues.

As technology evolves, cylinder deactivation may become standard. This could lead to even better fuel efficiency and performance in vehicles.

Frequently Asked Questions

What Are Gm Cylinder Deactivation Problems?

GM cylinder deactivation problems often involve engine stalling, rough idling, or decreased fuel efficiency.

How To Identify Cylinder Deactivation Issues?

Look for warning lights, unusual noises, or changes in engine performance during acceleration and deceleration.

Can Cylinder Deactivation Be Repaired?

Yes, cylinder deactivation can often be repaired by addressing faulty components or software updates in the engine system.

What Causes Cylinder Deactivation Failures?

Failures are usually due to defective sensors, solenoids, or issues with the engine’s control module.

Is Cylinder Deactivation Worth It?

While it improves fuel efficiency, some drivers report performance issues, making it a mixed benefit for many. “`

Conclusion

Gm cylinder deactivation issues can lead to performance concerns and driver frustration. Understanding these problems is crucial for effective maintenance and repair. Regular check-ups and timely interventions can mitigate risks. Stay informed about potential signs of trouble to ensure your vehicle runs smoothly.

Prioritize addressing these issues for better driving experiences.