Kohler V-Twin Ignition Coil Problems: Quick Fixes!

Kohler V-Twin ignition coil problems often stem from faulty coils or wiring issues. Symptoms include engine misfires, poor performance, or failure to start.

Kohler V-Twin engines are popular for their reliability and power in various applications. However, like any engine component, ignition coils can experience issues over time. These problems can lead to significant performance drops, making troubleshooting essential for maintaining efficiency. Owners might notice signs like rough idling, backfiring, or difficulty starting the engine.

Identifying and fixing ignition coil problems promptly can save time and money. Regular maintenance and inspections help catch issues early, ensuring your Kohler V-Twin runs smoothly. Understanding common symptoms and solutions empowers users to take action and keep their engines in top shape.

Introduction To Kohler V-twin Ignition Coil Issues

The Kohler V-Twin engine is popular for its power and reliability. However, it can face ignition coil issues. Understanding these problems helps in maintaining performance. Ignition coils play a crucial role in engine function. They convert battery voltage into high voltage for spark plugs.

Common Symptoms Of Failure

When the ignition coil fails, several symptoms may appear:

- Engine misfires: A noticeable lack of power.

- Hard starting: Difficulty in starting the engine.

- Stalling: Engine stops unexpectedly while running.

- Poor fuel economy: Decreased efficiency leads to more fuel usage.

- Check engine light: Illuminates on the dashboard.

Recognizing these signs early can save time and money.

Importance Of Timely Fixes

Addressing ignition coil issues quickly is vital. Delayed repairs can lead to more severe engine damage. Here are some reasons why timely fixes matter:

- Prevents further damage: Stops problems from worsening.

- Ensures engine efficiency: Maintains optimal performance.

- Reduces repair costs: Fixing small issues is cheaper.

- Enhances safety: Reduces the risk of engine failure.

Keeping your engine in top shape is essential for longevity.

Identifying Ignition Coil Problems

Detecting problems with your Kohler V-Twin ignition coil is crucial. Early detection can save time and money. Signs of a faulty ignition coil include engine misfires, rough idling, and poor acceleration. Knowing how to identify these issues can help you address them quickly.

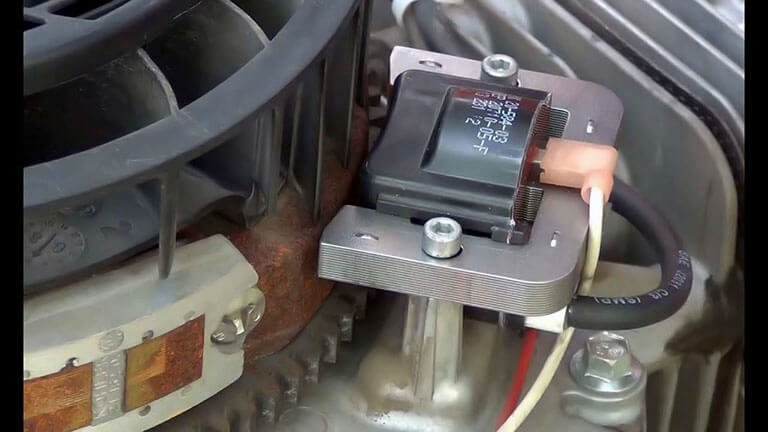

Visual Inspection Tips

A visual inspection is the first step. Look for the following signs:

- Cracks or damage: Inspect the coil for any visible cracks.

- Burn marks: Check for scorched areas on the coil.

- Corrosion: Look for rust or corrosion on connectors.

- Loose connections: Ensure all wires are tightly connected.

Cleaning the ignition coil can also help. Use a soft cloth and some electrical cleaner. This can remove dirt and debris that may cause issues.

Testing Coil With A Multimeter

Using a multimeter can help test the ignition coil. Follow these steps:

- Turn off the engine and disconnect the battery.

- Remove the ignition coil from the engine.

- Set the multimeter to the ohms setting.

- Connect the multimeter leads to the coil terminals.

- Check the resistance readings:

| Coil Type | Ohm Reading | Status |

|---|---|---|

| Primary Coil | 0.5 – 2.0 Ohms | Good |

| Secondary Coil | 5,000 – 20,000 Ohms | Good |

| Out of Range | N/A | Replace Coil |

Compare your readings to the values above. A reading outside the normal range indicates a problem. Replace the ignition coil if necessary.

Quick Fixes For Ignition Coil Troubles

Dealing with ignition coil issues in Kohler V-Twin engines can be frustrating. Quick fixes can help you get your engine running smoothly again. Below are two effective methods to tackle ignition coil problems.

Cleaning The Coil Contacts

Dirty coil contacts can cause poor engine performance. Follow these steps to clean them:

- Turn off the engine and disconnect the battery.

- Locate the ignition coil on your engine.

- Remove the coil from its mounting.

- Inspect the contacts for dirt and corrosion.

- Use a wire brush or sandpaper to clean the contacts.

- Wipe the area with a clean cloth to remove debris.

- Reinstall the ignition coil and reconnect the battery.

Regular cleaning helps maintain optimal performance. Always ensure the engine is cool before starting.

Adjusting The Coil Gap

The coil gap can affect ignition efficiency. Here’s how to adjust it:

- Turn off the engine.

- Remove the ignition coil carefully.

- Use a feeler gauge to check the gap.

- The ideal gap is usually between 0.010 and 0.020 inches.

- Adjust the gap by bending the coil tab gently.

- Recheck the gap with the feeler gauge.

- Reinstall the ignition coil securely.

Proper gap adjustment enhances spark delivery. Regular checks can prevent future issues.

Replacing The Ignition Coil

Replacing the ignition coil on a Kohler V-Twin engine can solve many ignition issues. A faulty ignition coil leads to poor engine performance. Understanding how to replace it properly is crucial for optimal functionality.

Choosing The Right Replacement

Selecting the correct ignition coil is vital. Here are some tips:

- Check the Model: Ensure compatibility with your engine model.

- OEM vs. Aftermarket: OEM parts offer reliability. Aftermarket may be cheaper.

- Read Reviews: Look for customer feedback on performance.

- Warranty: A good warranty can save costs in the long run.

Here’s a comparison table of popular ignition coils:

| Brand | Type | Price | Warranty |

|---|---|---|---|

| Kohler | OEM | $80 | 2 years |

| Stens | Aftermarket | $50 | 1 year |

| Briggs & Stratton | Aftermarket | $60 | 1 year |

Step-by-step Replacement Guide

Follow these steps to replace your ignition coil:

- Safety First: Disconnect the battery to avoid shocks.

- Remove Engine Cover: Unscrew and take off the cover.

- Locate Ignition Coil: Identify the faulty coil.

- Disconnect Wires: Carefully unplug the wires from the coil.

- Unscrew the Coil: Use a wrench to remove the mounting screws.

- Install New Coil: Position the new coil and secure it with screws.

- Reconnect Wires: Attach the wires to the new ignition coil.

- Replace Engine Cover: Screw the cover back in place.

- Reconnect Battery: Reattach the battery and test the engine.

Following these steps ensures a smooth replacement process. A new ignition coil can improve engine performance significantly.

Troubleshooting Spark Issues

Identifying spark issues in your Kohler V-Twin can be tricky. Spark problems often lead to engine performance issues. Proper troubleshooting can help you pinpoint the problem quickly.

Analyzing Spark Plug Conditions

Start by inspecting the spark plugs. They play a crucial role in ignition. Look for these signs:

- Color: A brownish tint indicates good performance.

- Wear: Look for cracks or signs of erosion.

- Carbon buildup: Excess buildup can cause misfires.

Replace any damaged or worn spark plugs. This simple step can resolve many ignition issues.

Testing For Spark Presence

Testing for spark presence is key to troubleshooting. Follow these steps:

- Remove the spark plug from the cylinder.

- Connect it to the ignition coil.

- Ground the spark plug against the engine frame.

- Crank the engine.

Observe the spark plug tip:

| Spark Presence | Action |

|---|---|

| Bright blue spark | Ignition coil is functioning properly. |

| No spark | Check the ignition coil and wiring. |

| Weak yellow spark | Replace the ignition coil. |

These tests help determine if the ignition system works correctly. Understanding spark presence is vital for troubleshooting.

Electrical System Maintenance

Maintaining the electrical system is crucial for the performance of Kohler V-Twin engines. Regular care prevents ignition coil problems and enhances engine longevity. Proper maintenance ensures smooth operation and reliability.

Regular Checks For Optimal Performance

Performing regular checks on your ignition coils is essential. Here are key steps to follow:

- Visual Inspection: Look for cracks or damage on the coils.

- Connection Check: Ensure all wires are securely connected.

- Resistance Testing: Use a multimeter to check coil resistance.

Schedule these checks every few months. This habit helps catch issues early.

Preventive Measures To Avoid Coil Failure

Taking preventive steps can save you from costly repairs. Consider the following:

- Keep Components Clean: Dirt can cause electrical problems.

- Avoid Overheating: Ensure the engine has proper cooling.

- Use Quality Parts: Always opt for OEM or high-quality replacements.

Implementing these measures reduces the risk of ignition coil failure.

| Action | Frequency | Benefit |

|---|---|---|

| Visual Inspection | Every Month | Catch damage early |

| Resistance Testing | Every 6 Months | Ensure proper function |

| Clean Components | Every Month | Prevent dirt buildup |

Expert Tips For Kohler V-twin Engines

Maintaining your Kohler V-Twin engine is crucial for performance. Ignition coil issues can cause problems. Here are expert tips to keep your engine running smoothly.

Professional Advice On Ignition System Care

Proper care of the ignition system is vital. Follow these tips:

- Regular Inspections: Check the ignition coils regularly for wear.

- Clean Connections: Keep all electrical connections clean and tight.

- Check Spark Plugs: Replace spark plugs as needed to avoid misfires.

- Use OEM Parts: Always choose Original Equipment Manufacturer parts for replacements.

Monitor performance. Pay attention to any unusual sounds or vibrations. Early detection prevents major issues.

Upgrades For Enhanced Performance

Boosting your engine’s performance can be simple. Consider these upgrades:

- High-Performance Ignition Coils: Upgrade to coils designed for better spark.

- Performance Spark Plugs: Use plugs that improve combustion.

- Enhanced Air Filters: Improve airflow to the engine for better efficiency.

- ECU Tuning: Reprogram your engine’s control unit for optimized performance.

These upgrades can enhance power and efficiency. Always consult a professional before making changes.

Faqs On Kohler V-twin Ignition Coil

The ignition coil is vital for your Kohler V-Twin engine. Understanding common issues helps maintain performance. Here are some frequently asked questions about ignition coil problems.

Addressing Common Concerns

Many users have similar questions about Kohler V-Twin ignition coils. Here are some common concerns:

- What are the signs of a faulty ignition coil?

- Common signs include:

- Engine misfires

- Difficulty starting

- Poor fuel efficiency

- Stalling while running

- How long do ignition coils last?

- On average, they last about 10,000 to 30,000 hours. Regular maintenance can extend their lifespan.

- Can I replace the ignition coil myself?

- Yes, replacing the ignition coil is manageable for DIY enthusiasts. Follow your manual for guidance.

- What causes ignition coil failure?

- Common causes include:

- Overheating

- Electrical issues

- Age and wear

- Moisture damage

Myths Vs. Facts About Ignition Coils

Many myths surround ignition coils. Here are some truths to clear confusion:

| Myth | Fact |

|---|---|

| All ignition coils are the same. | Different engines require specific ignition coils. |

| Ignition coils never fail. | They can wear out and need replacement. |

| High-performance coils are always better. | Stock coils are often sufficient for regular use. |

| Replacing one coil is enough. | It’s best to replace all coils simultaneously. |

Understanding these myths helps ensure better maintenance. Always consult your manual for specific requirements.

Frequently Asked Questions

What Are Common Kohler V-twin Ignition Coil Issues?

Common issues include misfiring, poor acceleration, and difficulty starting the engine.

How To Diagnose Ignition Coil Problems?

Check for spark at the spark plugs and inspect for visible damage or corrosion on the ignition coil.

Can A Faulty Ignition Coil Cause Engine Damage?

Yes, a faulty ignition coil can lead to engine misfires, which may damage other components over time.

What Are Signs Of A Bad Ignition Coil?

Signs include rough idling, engine stalling, and decreased fuel efficiency.

How To Replace A Kohler Ignition Coil?

Disconnect the battery, remove the old coil, and install the new one, ensuring proper connections.

Conclusion

Kohler V-Twin ignition coil issues can lead to engine performance problems. Regular maintenance and timely replacements are crucial for optimal function. Addressing these concerns early can save you from costly repairs. Stay informed about symptoms and solutions to keep your equipment running smoothly.

Knowledge is key to preventing future complications.