Gearbox Sensor Problems: Quick Fixes for Smooth Driving

Gearbox sensor problems can lead to erratic shifting and poor vehicle performance. Diagnosing these issues early can prevent costly repairs.

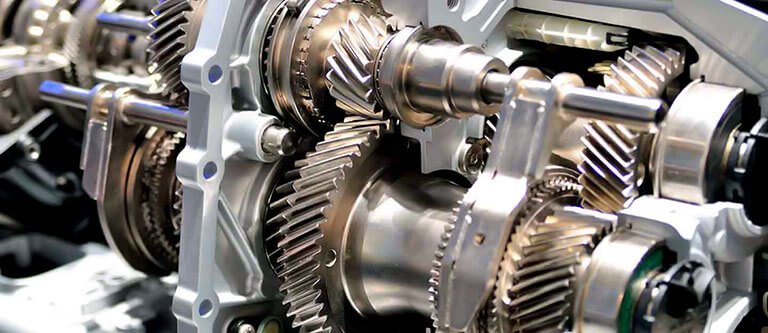

Gearbox sensors play a crucial role in modern vehicles, helping to manage shifting and overall transmission performance. These sensors monitor various parameters, ensuring that your car shifts smoothly and efficiently. When they malfunction, drivers may experience issues such as slipping gears, delayed shifts, or even a complete transmission failure.

Understanding common symptoms can help you identify problems early. Regular maintenance and timely diagnostics can keep your vehicle running smoothly. By addressing gearbox sensor issues promptly, you can save money and enhance your driving experience. Awareness of these components not only helps in troubleshooting but also ensures better vehicle longevity and performance.

Introduction To Gearbox Sensor Issues

Gearbox sensors play a crucial role in vehicle performance. They monitor the transmission’s operation and provide vital data. Problems with these sensors can lead to various issues. Understanding these issues helps in maintaining a smooth driving experience.

Common Symptoms Of Faulty Sensors

Faulty gearbox sensors can cause noticeable symptoms. Here are some common signs to watch for:

- Erratic Shifting: Gears may shift unexpectedly.

- Delayed Engagement: There might be a delay in gear changes.

- Warning Lights: The check engine light may illuminate.

- Unusual Noises: Grinding or whining sounds may occur.

- Slipping Gears: Gears may slip out unexpectedly.

Impact On Vehicle Performance

Faulty sensors can severely affect vehicle performance. Here are some impacts:

| Impact | Description |

|---|---|

| Reduced Fuel Efficiency | Inaccurate data leads to improper fuel usage. |

| Increased Wear | Components wear out faster due to incorrect operation. |

| Safety Risks | Unexpected behavior can lead to accidents. |

Addressing gearbox sensor issues promptly is essential. Regular maintenance checks can prevent major problems.

Types Of Gearbox Sensors

Gearbox sensors play a crucial role in vehicle performance. They monitor different aspects of the gearbox. Understanding the types of gearbox sensors helps in troubleshooting issues effectively.

Speed Sensors

Speed sensors measure the rotational speed of the gearbox. They provide vital information to the engine control unit (ECU).

- Common types include:

- Magnetic sensors

- Hall effect sensors

- Optical sensors

Speed sensors help in various ways:

- Improving gear shifting.

- Enhancing fuel efficiency.

- Preventing engine damage.

Malfunctioning speed sensors can cause:

- Rough shifting.

- Increased fuel consumption.

- Check engine light activation.

Temperature Sensors

Temperature sensors monitor the heat levels within the gearbox. They ensure the gearbox operates within safe limits.

Key functions of temperature sensors include:

- Detecting overheating.

- Preventing fluid breakdown.

- Maintaining optimal performance.

Common issues with temperature sensors are:

- Incorrect readings.

- Sensor failure.

- Damage from extreme temperatures.

| Issue | Symptoms |

|---|---|

| Overheating | Warning lights, burning smell |

| Incorrect readings | Poor gear performance |

Regular checks on both speed and temperature sensors ensure smooth operations. Proper maintenance prevents costly repairs.

Diagnosing Gearbox Sensor Failures

Diagnosing gearbox sensor failures is essential for vehicle performance. A malfunctioning sensor can affect shifting and overall driving experience. Early detection can save time and money.

Tools Required For Diagnosis

- OBD-II Scanner: Reads error codes from the vehicle.

- Multimeter: Tests electrical signals and continuity.

- Socket Set: For removing and replacing sensors.

- Wiring Diagram: Helps understand sensor connections.

- Digital Torque Wrench: Ensures bolts are tightened correctly.

Step-by-step Diagnostic Process

- Check for Error Codes: Use an OBD-II scanner to find codes.

- Inspect Wiring: Look for frayed or damaged wires.

- Test Sensor with Multimeter: Measure voltage and resistance.

- Compare Readings: Match with manufacturer specifications.

- Clear Error Codes: Reset the system after repairs.

- Test Drive: Ensure proper function after repairs.

Following these steps can help identify gearbox sensor issues. Regular checks can prevent future problems and enhance vehicle reliability.

Simple Fixes For Gearbox Sensor Problems

Gearbox sensor problems can cause various issues in your vehicle. These issues affect shifting, performance, and safety. Luckily, many problems can be fixed easily. Here are two simple fixes that can help restore your gearbox sensor’s function.

Cleaning Sensor Contacts

Dirty sensor contacts can lead to faulty readings. Cleaning them can solve many problems. Follow these steps:

- Locate the gearbox sensor.

- Disconnect the battery for safety.

- Remove the sensor from its mount.

- Use a soft cloth to wipe the contacts.

- Apply electrical contact cleaner to the contacts.

- Reconnect the sensor and battery.

Cleaning the contacts restores proper function. Regular maintenance can prevent future issues.

Resetting The Gearbox Sensor

Resetting the gearbox sensor can fix errors. This process is quick and straightforward:

- Turn off the engine.

- Disconnect the battery terminals.

- Wait for at least 10 minutes.

- Reconnect the battery terminals.

- Start the engine.

Resetting clears error codes. This action helps the gearbox sensor recalibrate.

Always check for any lingering issues after resetting. If problems persist, consult a professional.

When To Replace Gearbox Sensors

Gearbox sensors play a crucial role in vehicle performance. They monitor various functions and provide essential data. Knowing when to replace them can prevent serious issues. Look for signs of malfunction to avoid costly repairs.

Lifespan Of Gearbox Sensors

Gearbox sensors typically last between 50,000 to 100,000 miles. Factors affecting lifespan include:

- Quality of the sensor

- Driving conditions

- Vehicle maintenance

Signs that sensors may need replacement include:

| Sign | Description |

|---|---|

| Check Engine Light | This light often indicates sensor issues. |

| Slipping Gears | Difficulty in changing gears may signal a problem. |

| Poor Fuel Economy | Increased fuel consumption can suggest faulty sensors. |

Choosing The Right Replacement

Selecting the correct replacement sensor is vital. Consider the following factors:

- Compatibility: Ensure the sensor fits your vehicle model.

- Brand: Choose a reputable brand for reliability.

- Warranty: Look for sensors with a good warranty.

Consult a mechanic for recommendations. Proper installation is essential for optimal performance.

Preventive Measures To Avoid Sensor Issues

Preventive measures help keep your gearbox sensors in top shape. Regular check-ups and good driving habits can save you time and money. These steps will reduce the risk of sensor problems.

Regular Maintenance Tips

Staying on top of maintenance is crucial. Follow these tips:

- Check Fluid Levels: Ensure transmission fluid is at the right level.

- Change Fluid Regularly: Follow manufacturer guidelines for fluid changes.

- Inspect Wiring: Look for frayed or damaged wires.

- Clean Sensors: Remove dirt and debris from sensors.

Consider scheduling a professional inspection once a year. This can catch problems early.

Driving Habits To Prolong Sensor Life

Your driving habits impact sensor health. Adopt these practices:

- Avoid Hard Shifting: Shift gears smoothly to reduce stress.

- Don’t Overload: Avoid carrying heavy loads that strain the gearbox.

- Use Engine Braking: Use brakes gently instead of downshifting hard.

- Limit Stop-and-Go Driving: Avoid frequent stops to reduce wear.

Good driving habits can extend sensor life significantly. Protect your vehicle with these simple changes.

Understanding Error Codes Related To Gearbox Sensors

Gearbox sensors play a crucial role in vehicle performance. They monitor various aspects of the gearbox. Understanding error codes can help diagnose issues quickly. This knowledge saves time and money during repairs.

Interpreting Obd-ii Codes

OBD-II codes are standardized codes used in vehicles. Each code gives specific information about a problem. These codes start with a letter followed by four digits. The letter indicates the system affected.

- P – Powertrain issues

- B – Body issues

- C – Chassis issues

- U – Network issues

For gearbox sensors, focus on the Powertrain codes. These codes relate directly to the engine and transmission. Here’s how to read them:

- The first character indicates the system.

- The second character shows the specific issue.

- The last two characters provide additional details.

Common Gearbox Sensor Error Codes

Here are some common gearbox sensor error codes:

| Error Code | Description |

|---|---|

| P0700 | Transmission Control System Malfunction |

| P0715 | Transmission Fluid Temperature Sensor Malfunction |

| P0720 | Output Speed Sensor Circuit Malfunction |

| P0730 | Incorrect Gear Ratio |

| P0740 | Torque Converter Clutch Circuit Malfunction |

Each error code points to a specific issue. Knowing these codes helps in troubleshooting. Understanding the symptoms associated with each code is essential. This knowledge leads to faster repairs and better vehicle performance.

Professional Repair Vs. Diy For Sensor Problems

Deciding between professional repair and DIY fixes for gearbox sensor problems can be tough. Both options have their pros and cons. Understanding when to seek help is key. Knowing resources for DIY repairs also helps. This guide will clarify your choices.

When To Seek Professional Help

Some sensor issues require expert attention. Here are situations where you should call a professional:

- Complex Symptoms: If multiple sensors malfunction.

- Advanced Diagnostics: When specialized tools are needed.

- Warranty Concerns: If your vehicle is still under warranty.

- Safety Issues: If problems affect vehicle safety.

Trust professionals for accurate diagnosis. They have experience with gearbox systems. Experts can save you time and money in the long run.

Resources For Diy Repairs

DIY repairs can be rewarding and cost-effective. Here are resources to help you:

| Resource Type | Description |

|---|---|

| Online Tutorials | Videos and articles that show step-by-step repairs. |

| Forums | Communities where you can ask questions and share experiences. |

| Repair Manuals | Detailed guides specific to your vehicle model. |

| Diagnostic Tools | Devices that help you read error codes from the vehicle. |

Before starting a DIY project, gather all necessary tools. Ensure you understand the steps involved. Always prioritize safety during repairs.

The Future Of Gearbox Sensors In Vehicles

The future of gearbox sensors in vehicles is bright. Rapid advancements in technology are changing how we drive. These sensors play a vital role in enhancing vehicle performance. They help ensure smoother gear transitions and better fuel efficiency.

Technological Advancements

New technologies are improving gearbox sensors. These advancements include:

- Smart Sensors: These sensors can adapt to driving conditions.

- Wireless Communication: This reduces wiring complexity and weight.

- Data Analytics: Sensors collect data to optimize performance.

Manufacturers are investing in research. They aim to create sensors that last longer and work better. The integration of artificial intelligence will also help. AI will allow sensors to predict issues before they occur. This proactive approach minimizes repair costs.

Impact On Automotive Industry

Gearbox sensors significantly impact the automotive industry. Here are some key effects:

| Impact Area | Description |

|---|---|

| Safety: | Improved sensors enhance vehicle safety and performance. |

| Fuel Efficiency: | More accurate sensors lead to better fuel economy. |

| Maintenance: | Predictive analytics reduce unexpected repairs. |

| Cost Savings: | Longer-lasting sensors lower overall vehicle costs. |

These improvements will attract more buyers. Consumers desire safer and more efficient vehicles. The automotive industry must adapt quickly to these changes. Staying ahead means investing in advanced gearbox sensor technology.

Frequently Asked Questions

What Are Common Gearbox Sensor Problems?

Common gearbox sensor problems include faulty readings, electrical issues, and wear and tear affecting performance.

How Do I Identify Gearbox Sensor Issues?

Look for warning lights, erratic shifting, or unusual noises indicating potential gearbox sensor issues.

Can I Drive With A Faulty Gearbox Sensor?

Driving with a faulty gearbox sensor can lead to poor performance and potential damage. It’s best to address it promptly.

What Causes Gearbox Sensor Failure?

Gearbox sensor failure can be caused by electrical faults, physical damage, or contamination from fluids over time.

How To Fix Gearbox Sensor Problems?

Fixing gearbox sensor problems often requires diagnostic testing, repairs, or replacement by a qualified mechanic for best results.

Conclusion

Gearbox sensor problems can lead to serious vehicle issues. Identifying symptoms early can save time and money. Regular maintenance is crucial for optimal performance. If you notice any irregularities, consult a professional immediately. Being proactive ensures your vehicle remains safe and efficient on the road.

Stay informed to avoid future complications.